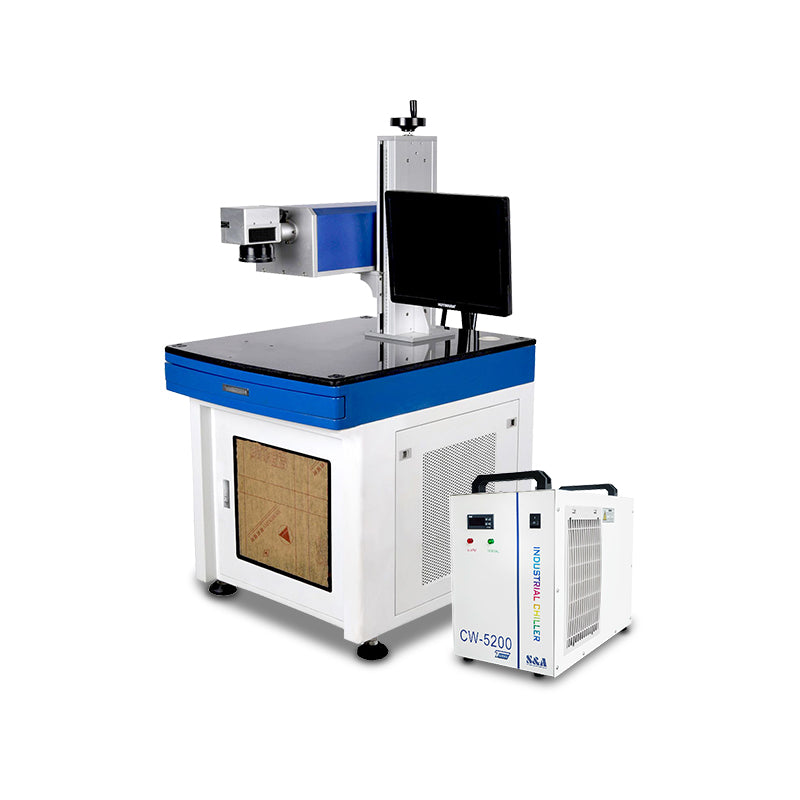

An all-in-one UV laser marking solution with a fully enclosed cabinet design for safety and cleanliness. Ideal for high-precision marking on plastics, glass, ceramics, and electronic components. Compact, efficient, and perfect for cleanroom or industrial environments.

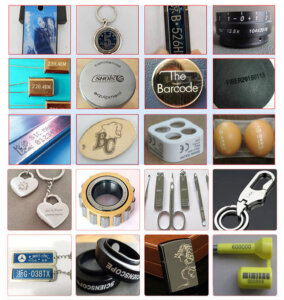

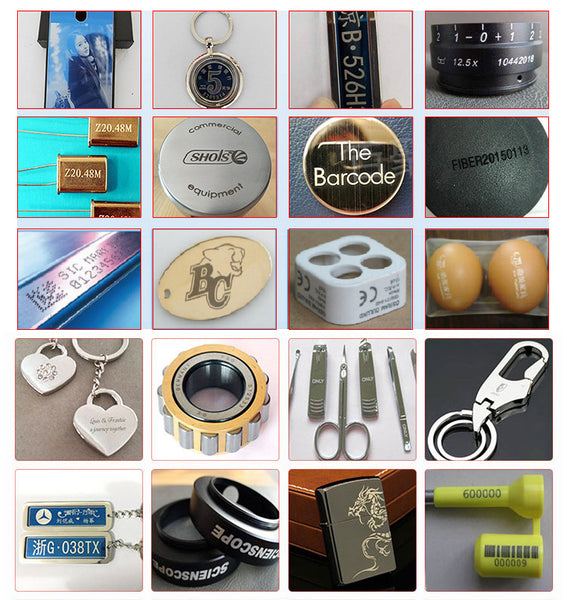

Application Industry:

Mainly used in the hyper fine high end handling industries, high-end market of ultra-fine processing, such as electronic products, food, medicine, medical devices, cosmetics, glassware, electronic components, medical components, light fixtures, gifts, lamps, Air craft, PVC, communication equipment and other industries.

Applicable Material:

It can be applied on Silk fabric, cotton fabric, Mainly used in all kinds of glass, LCD screen, plasma exhibition, textiles, thin ceramic, single silicon wafers, polymer film, polymer and other materials marking and surface treatment, the

material on the market can basically be market decorative fabric, polyester fabric, chemical fiber fabric, pure hemp fabric, leather, artificial leather, decorative , packaging leather, soft leather, rubber, acrylic, wood, paper and all kinds of clothing accessories etc.

Specifications – Cabinet Integrated UV Laser Marking Machine

-

Laser Type: Ultraviolet (UV) Laser

-

Wavelength: 355 nm

-

Laser Power: 3W / 5W / 10W / 15W

-

Marking Area: 100×300 mm

-

Marking Speed: ≤7000 mm/s

-

Marking Depth: ≤0.1 mm (depends on material)

-

Repetition Accuracy: ±0.01 mm

-

Cooling Method: Air-cooled or water-cooled (based on power)

-

Machine Structure: Fully enclosed safety cabinet with observation window

-

Control Software: EZCAD

-

Supported File Formats: PLT, BMP, DXF, JPG, AI, SVG, etc.

-

Supported Materials: Plastics, glass, ceramics, silicon, rubber, coated/painted materials

-

Power Supply: AC 220V ±10%, 50/60Hz

-

Optional Features: Rotary axis, auto-focus, fume extractor, touch screen panel

-

Working Environment: 15°C–30°C, humidity ≤75% RH

-

Safety Features: Laser safety interlock, light-proof housing, emergency stop

Reviews

There are no reviews yet.